Summary of the composite coatings application method.

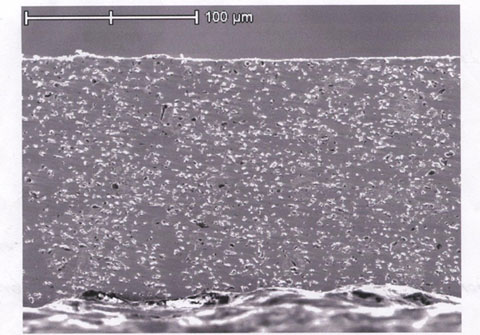

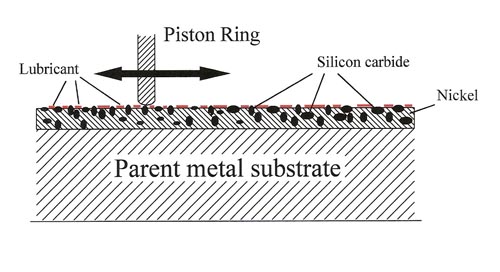

Method of Nikasil composite coating application was developed in 1972 by Mahle company, Germany. Nikasil is a brand name consisting of the following elements being its components: nickel matrix (Ni) and wear-resistant constituent of silicon carbide – SiC.

Thereafter, similar galvanic coatings were developed, such as Nicom, Electrosil, Revasil, as well as а Kawasaki branded coating, Microarc oxidation (MAO) coating and others.

Today almost all aluminum cylinders of an extreme equipment have one or another kind of a coatings, and cast-iron bushings remaine only in old models, whereby American manufacturers Wisseko, LASleeve produce repair kits, which include a cast-iron bushing + a piston.

Pistons for coated cylinders are manufactured for the entire operating life and are of one standard size. Operating life of such cylinders is 3 times as long as that of cylinders with cast-iron bushings.

For a racing equipment enduring much higher loads than a road equipment (a piston guaranteed service life makes 1.5 hours for a carting and 25 hours for a motocross), 4-7 pistons are made with 0.01 mm size interval. When pistons are replaced, a group with a bigger piston size is chosen, if required.

Our repair works involve removal of old coating, welding-up of deteriorations (if necessary), application of a new coating and grinding with subsequent honed finishing to the righ.