The need to repair aluminum cylinders arose in the states of the former USSR at the end of the last century with the appearance of modern sports equipment in motocross and carting sports, and so the first experimental works refer to that period. In 2002, we set up a laboratory for repair of cylinders using the method of composite coating galvanic recovery, more specifically application of Nikasil-type composite coating.

At present, we repair mono-cylinders and double-cylinder blocks for motorcycles, snowmobiles, wave runners, steam prime movers and other extreme equipment.

We work with customers from Ukraine, Russia, Belarus, Kazakhstan and Moldova.

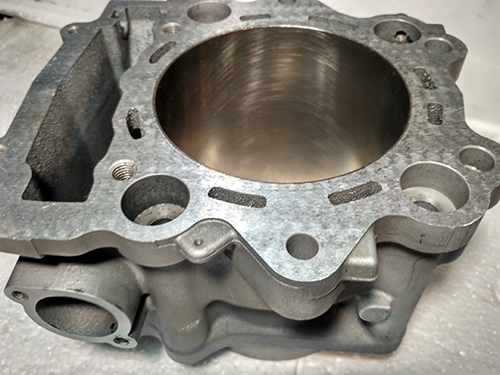

We categorize repair works as simplified repair and complex repair. Simplified repair is performed in case of natural wear of surfaces in service, while complex repair is performed when an accident causes rings breakage, bearings collapse or emerging dints and cracks, or when detonation with further overheating takes place what results in cylinder damage. In the above cases of complex repair, deteriorations need to be welded up and lost elements should be recovered.

Advantages of repair by means of Nikasil composite coating application as compared to repair with cast-iron bushing have been described in many articles. These can be easily found on the Internet. In short, wear resistance of composite-coated surfaces is 3 times higher, and equal thermal expansion coefficient of cylinder and piston material means that when heated, a cylinder and a piston increase in size equally, thus smaller expansion gap between a cylinder and a piston is required; a silicon carbide has an ability of oil absorption, so leading to friction reduction.